Corner Conservatory - Spring Semester, 2010

This was my first independent studio. Here we were taken

from start to finish on a typical product design & prototype. We spent the

first days talking about best practices, research, and discussing what types of

products we'd like to work on redesigning. A very fun "enjoy it while you

can, you won't always be able to just pick what you want to work on" sort

of project.

As a class, we settled on three groups: camping equipment, food storage/prep, and home gardening devices (think "Aerogarden"). I knew nothing about camping, or cooking, or gardening, so I figured gardening would be interesting. We split into three small teams, each tackling a different product segment. Each group then did extensive research on the existing products within their area, and presented those findings to the rest of the studio.

Though each team was focused on a different product segment, and each individual their own project, the research could generally be broken down into a few key areas. We researched what products were already out there, what people did and didn't like about existing products, how those products could be made better, and how people wanted to be able to use specific products. We treated each individual product as if we were designing it for a competing company, filling a niche that was under-served and solving the problems that consumers had with existing products.

There were a number of issues that I had discovered during my research, and these became the key challenges that I wished to address. One of the most common complaints about the Aerogarden was that it required proprietary items, such as lights, seed pods, etc. that could not be bought at local stores and tended to be expensive. Therefore one of my most important tasks was making certain as many replaceable pieces as possible should be able to be bought at any local big-box home and garden retailer. Another fairly common complaint was that of people's pets getting into the exposed Aerogarden. Many people lamented the lack of a cover or door. Lastly, our designs needed to have a distinctly different look from other existing products.

As a class, we settled on three groups: camping equipment, food storage/prep, and home gardening devices (think "Aerogarden"). I knew nothing about camping, or cooking, or gardening, so I figured gardening would be interesting. We split into three small teams, each tackling a different product segment. Each group then did extensive research on the existing products within their area, and presented those findings to the rest of the studio.

Though each team was focused on a different product segment, and each individual their own project, the research could generally be broken down into a few key areas. We researched what products were already out there, what people did and didn't like about existing products, how those products could be made better, and how people wanted to be able to use specific products. We treated each individual product as if we were designing it for a competing company, filling a niche that was under-served and solving the problems that consumers had with existing products.

There were a number of issues that I had discovered during my research, and these became the key challenges that I wished to address. One of the most common complaints about the Aerogarden was that it required proprietary items, such as lights, seed pods, etc. that could not be bought at local stores and tended to be expensive. Therefore one of my most important tasks was making certain as many replaceable pieces as possible should be able to be bought at any local big-box home and garden retailer. Another fairly common complaint was that of people's pets getting into the exposed Aerogarden. Many people lamented the lack of a cover or door. Lastly, our designs needed to have a distinctly different look from other existing products.

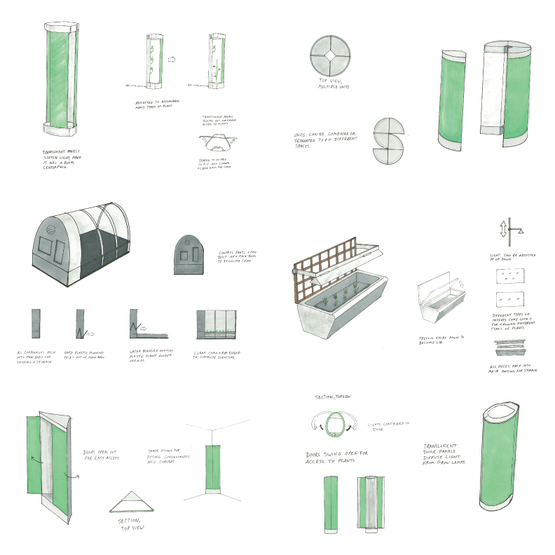

We began with rough concepts that addressed the issues we had discovered during our research. Along with utilizing replacement parts that were commonly available, and finding ways to keep pets out of the units, another challenge was addressing the issue of what could be grown in the unit. A number of people had expressed an interest in being able to grow larger or taller plants than were currently able to be grown in an Aerogarden.

After presenting our initial ideas and discussing them with the studio, we refined our concepts.

After another round of presentation and discussion, we each settled on our final idea to prototype.

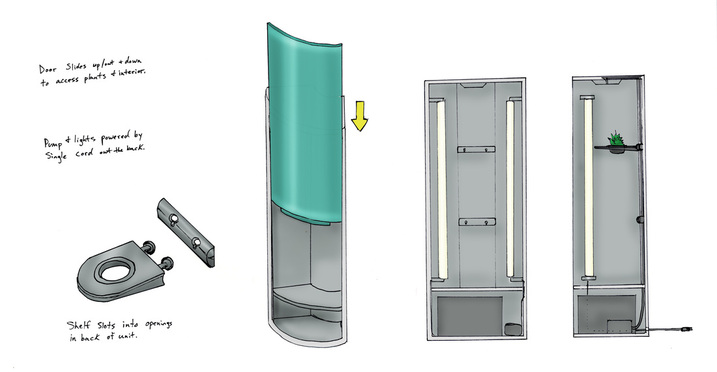

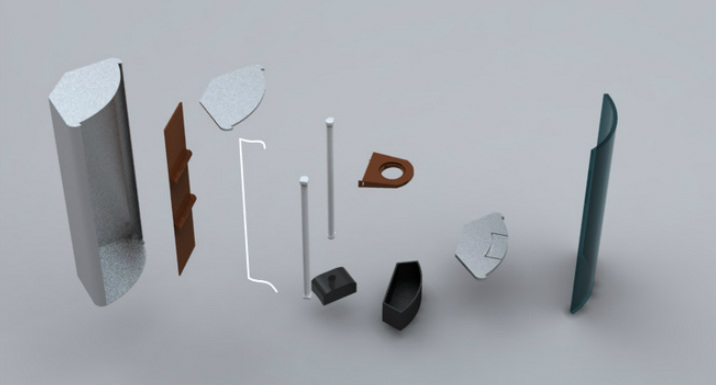

An early Solid Edge model of the product. We were taking our Solid Edge 3d modeling class that semester and were tasked with building a CAD model of our project to show how it would fit together.

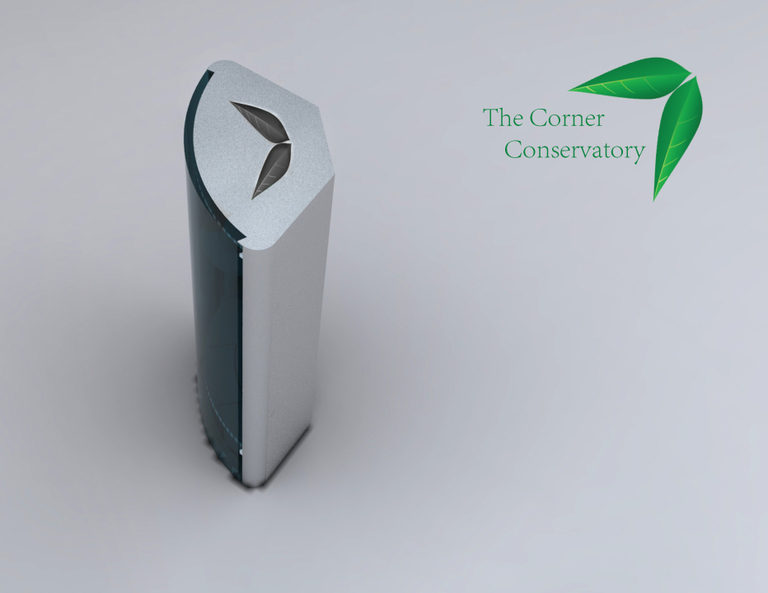

Branding exercise.

Finished prototype, with cover insert. The body of the prototype was made from bent anodized aluminum sheet. The cover is a thin, matte, flexible plastic and slides down through a channel formed by the body of the unit and the outer edge of the shelves. The cover addressed many users' complaints about their pets getting into the plants in their home gardening units.

Finished prototype without main cover. The cover was produced in two separate parts so that the workings of the system could remain covered even when the main cover was removed.

Our gardening crew got to learn an awful lot about hydroponics for this project. Jokes aside, How-to-Hydroponics was a really useful book, and a little more in line with the research we had been trying to find. After researching the different types of hydroponics systems out there, I went with a drip system. I used a standard aquarium pump and clear plastic tubing for the irrigation system. The water/nutrient solution is pumped up from the reservoir, drips from the top down through the top cup, and on down through the hole in each cup to return to the reservoir at the bottom. Though I used a small plastic container, any dish or small tub could be used as a reservoir. That way, if you need to clean or replace it, you're not stuck having to buy a special replacement.

For the lights, I used two standard florescent grow-lights that can be picked up most anywhere, powered by a low-profile ballast tucked behind a lacquered wooden back-plate. The lighting brackets were epoxied straight to the aluminum shell. The lights and drip system can be put on a timer, and all electronics run on one standard wall plug.

The shelves and cup inserts were laser-cut acrylic painted to match the aluminum case. A keyhole eyelet system along the back plate allowed for removing or adjusting the height of the grow-cups to accommodate different sized plants. The lower cover can be removed to get at the pieces contained within, but the middle section of the shelf can be removed for easy access when it's time to add water to the reservoir.

The Corner Conservatory in action, plugged up and running.