Assorted Fabrication

Though I had many full-semester studios, I also had a number of smaller fabrication projects. These projects may not have taken as much time, but they did each present their own challenge.

Monument sign mock-up for an early branding project (same semester as the Blind Pig project). Sign face, lettering, and base pieces are laser-cut acrylic, spray painted then epoxied into place. Sign face is 1/16" acrylic, lettering and logo is 1/8" acrylic. This way, I could guarantee a uniform height of the raised bits. The section between the two acrylic faces of the sign and the section between the two base-plates are both spray-painted poster board. The paint adheres well, and gives the poster board a little extra stiffness while still remaining flexible enough to wrap around corners without creasing or flaking.

Other side of monument sign, with push-button. I wanted to give a feel for what the sign would look like at night.

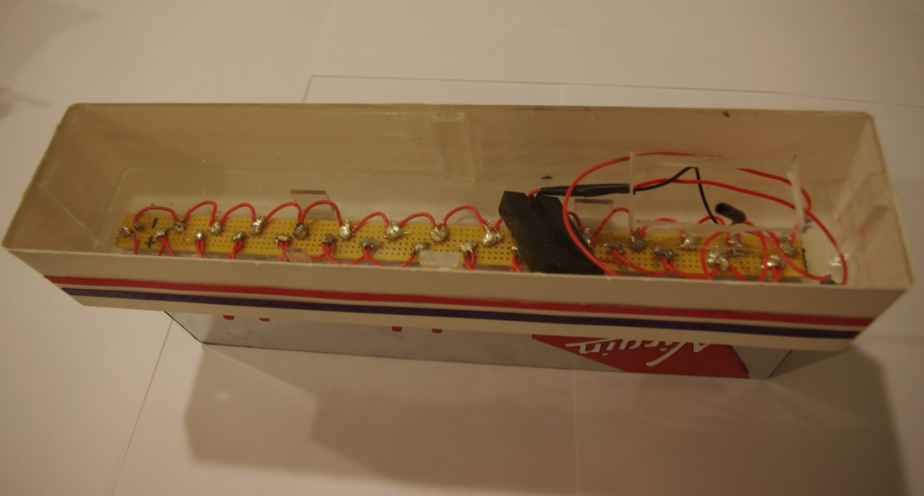

Underbelly and innards came from Radio Shack. I chopped down a breadboard to size, and soldered in some LEDs powered by 2 AA batteries.

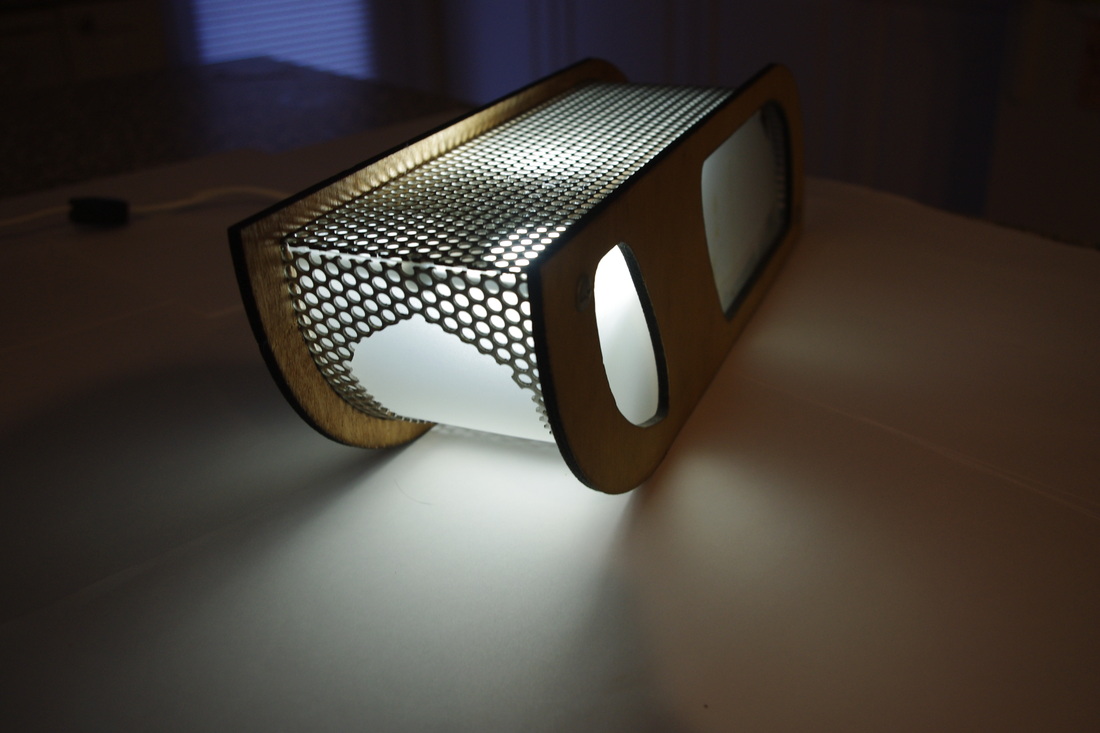

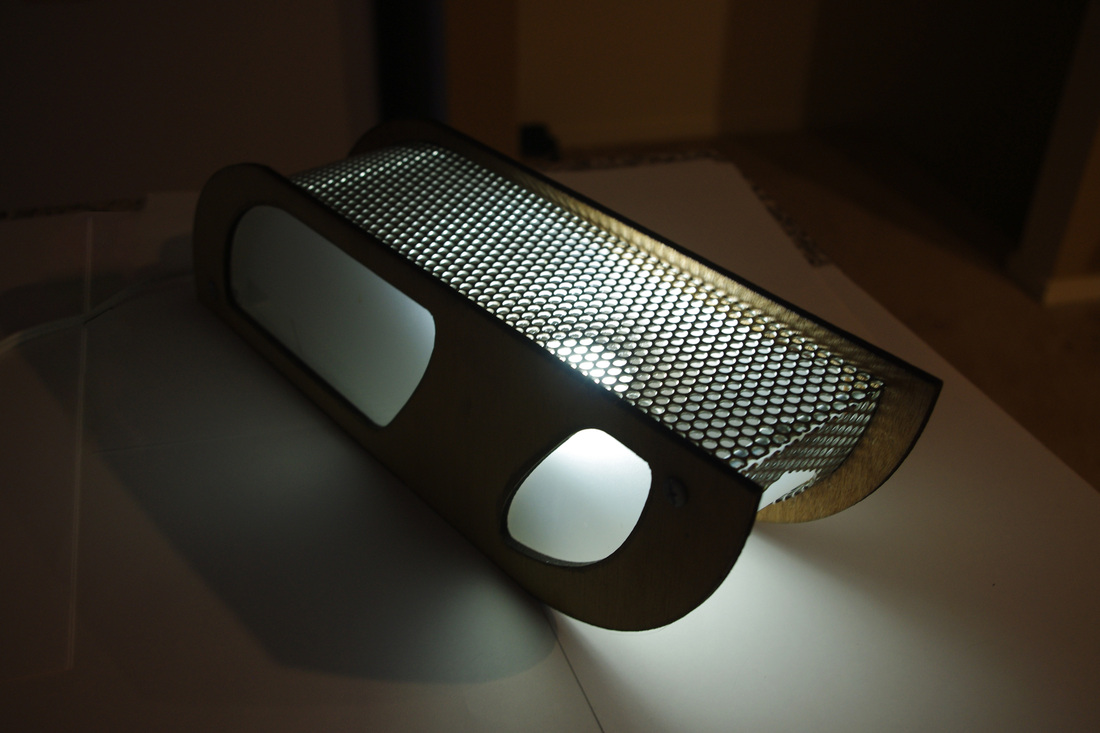

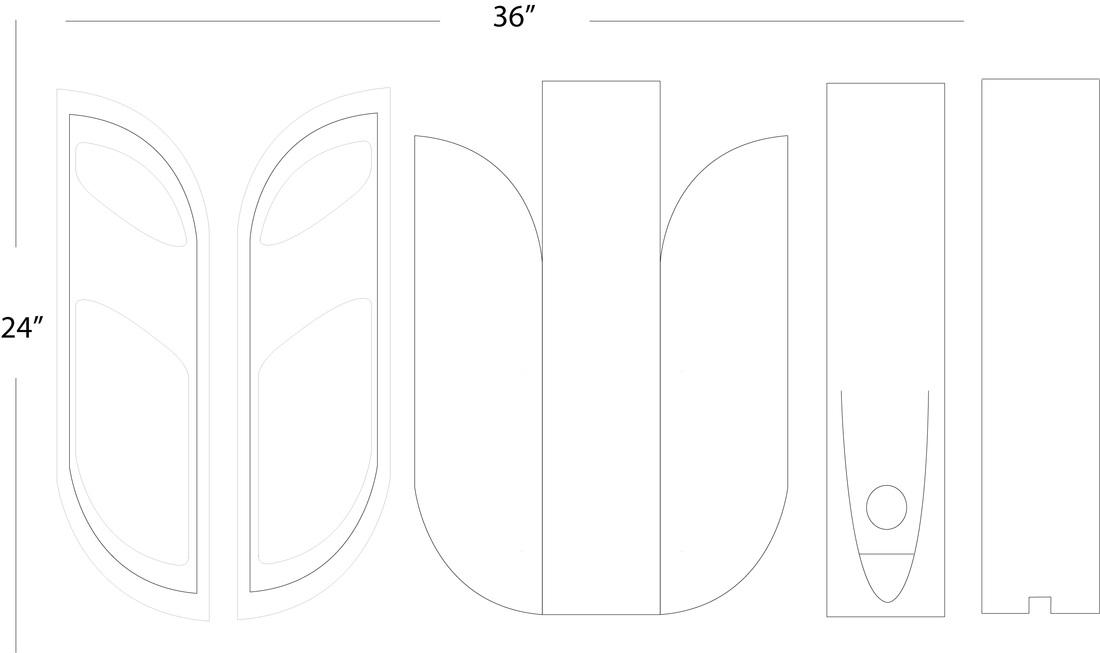

"Flat-pack Lamp." An even earlier project, going all the way back to Spring 2010. An early exercise in design/manufacturing considerations, specifically, design a flat pack lamp. That is, a packet of pieces that utilized a minimum amount of material and could be shipped flat and assembled upon arrival by the purchaser.

We were allowed to use whatever materials we wanted in whatever combinations, but all pieces had to be able to fit on one 24" x 36" sheet.

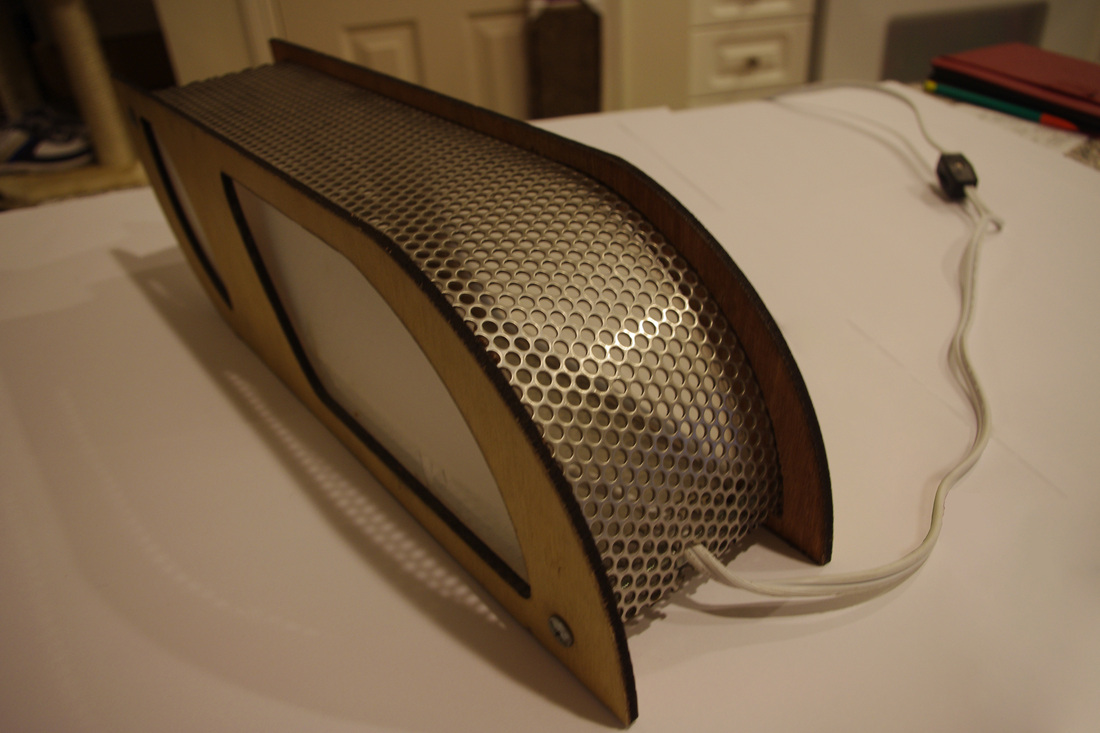

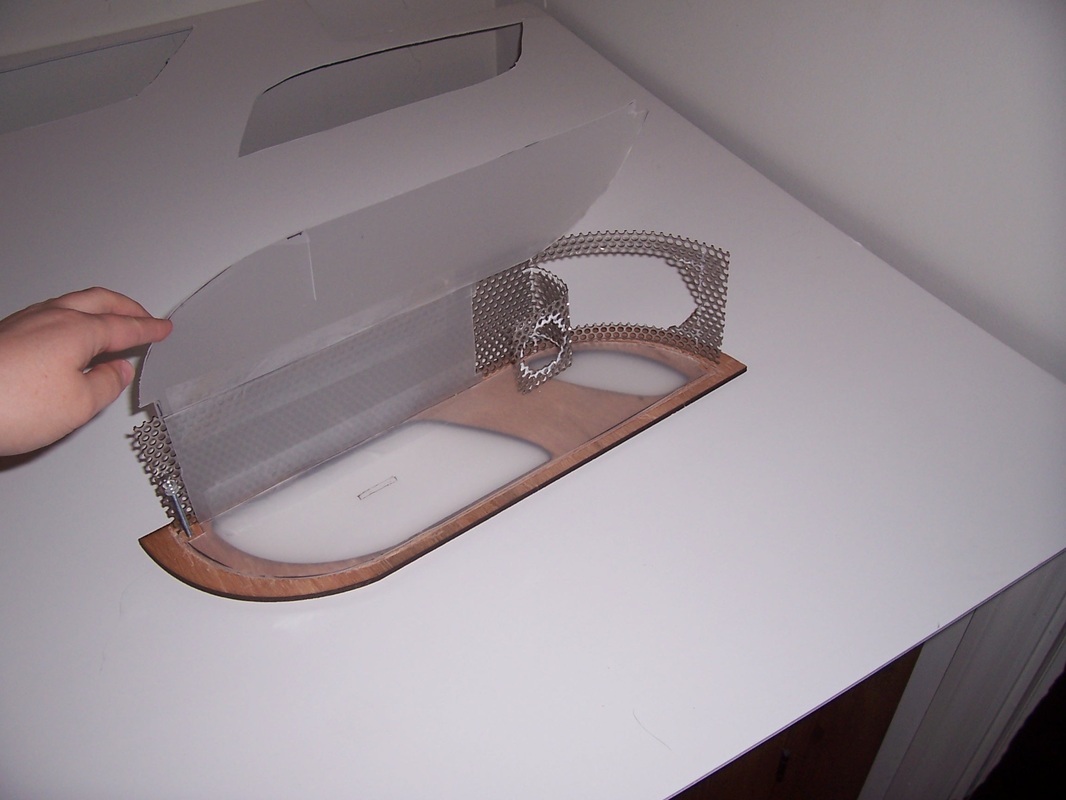

Jumble of pieces before assembly. Metal pieces after being bent into a proper fit.